The management of machinery, equipment, and their maintenance

Planning the maintenance and risk assessment of machines and work equipment is a fundamental activity for any company, in addition to being legally required under current regulations.

Failure to maintain machinery can lead to breakdowns and malfunctions, and in the worst cases, can cause serious accidents. If not managed properly, these events can halt production and result in economic losses for the company. Furthermore, in the event of an accident, the company owner may be held criminally liable.

Our clients

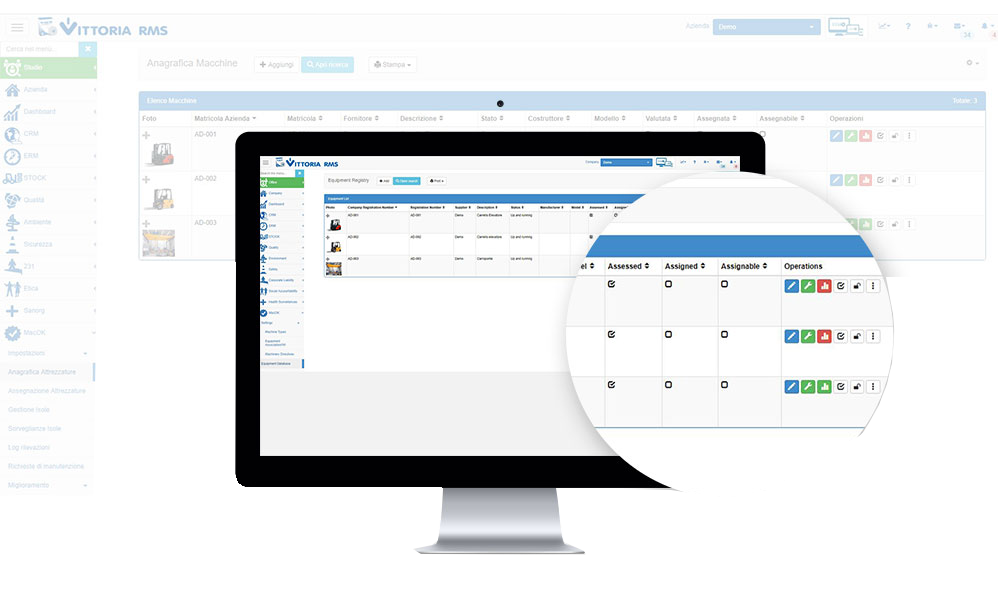

Our Software for Machinery Management and Maintenance

With Vittoria RMS, you can create machinery maintenance plans, assign monitoring tasks, and perform risk assessments in accordance with the provisions of the new Machinery Directive, all in an efficient and streamlined way.

All collected data is easily accessible and always up to date.

In the event of extraordinary maintenance or unexpected issues, it is possible to report events, create an approval workflow, and track the implemented measures.

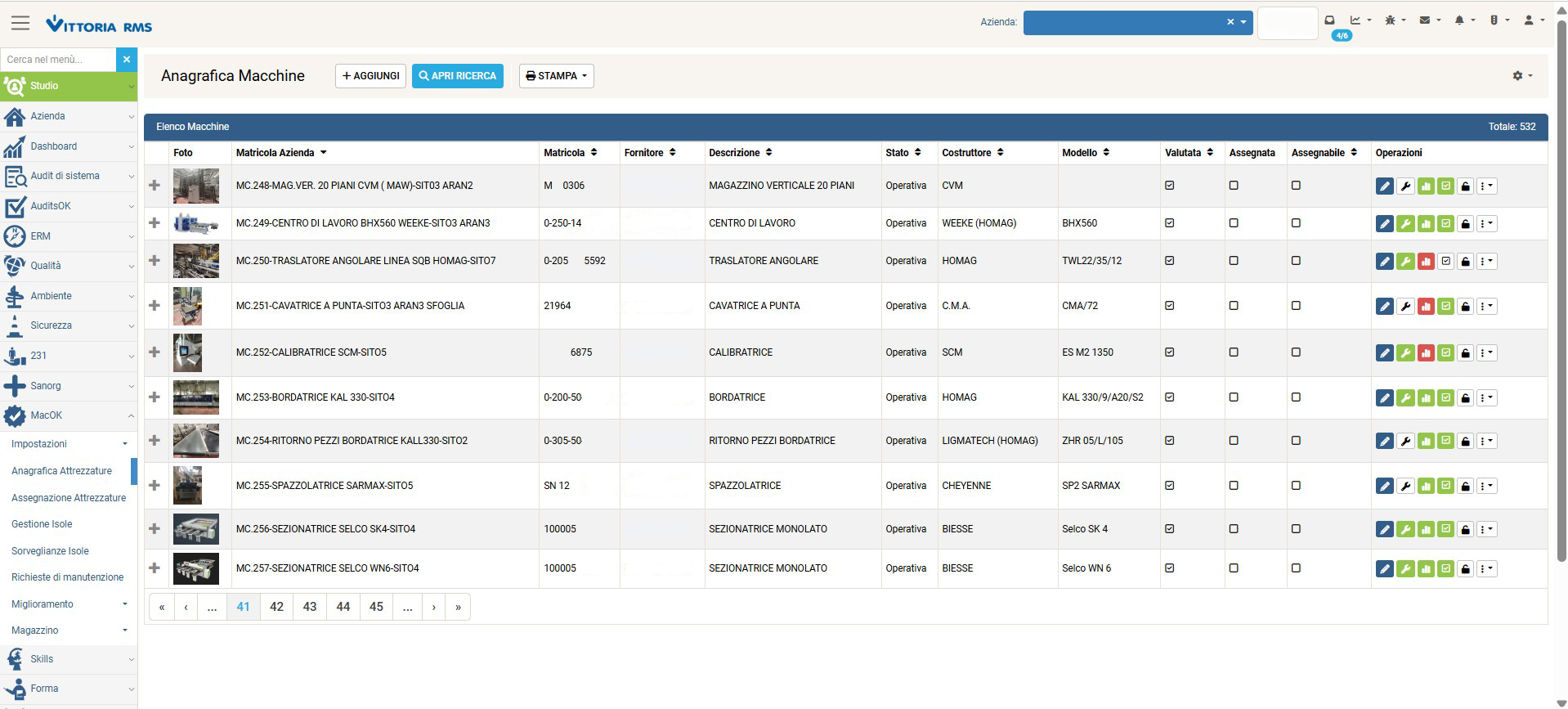

Record all your assets data

- Collect data on your equipment (machinery, devices, etc.) by directly accessing all related documents, and record routine maintenance in accordance with regulatory compliance.

- Assess the risk associated with your machines.

- Create and manage document checklists where you can monitor all deadlines.

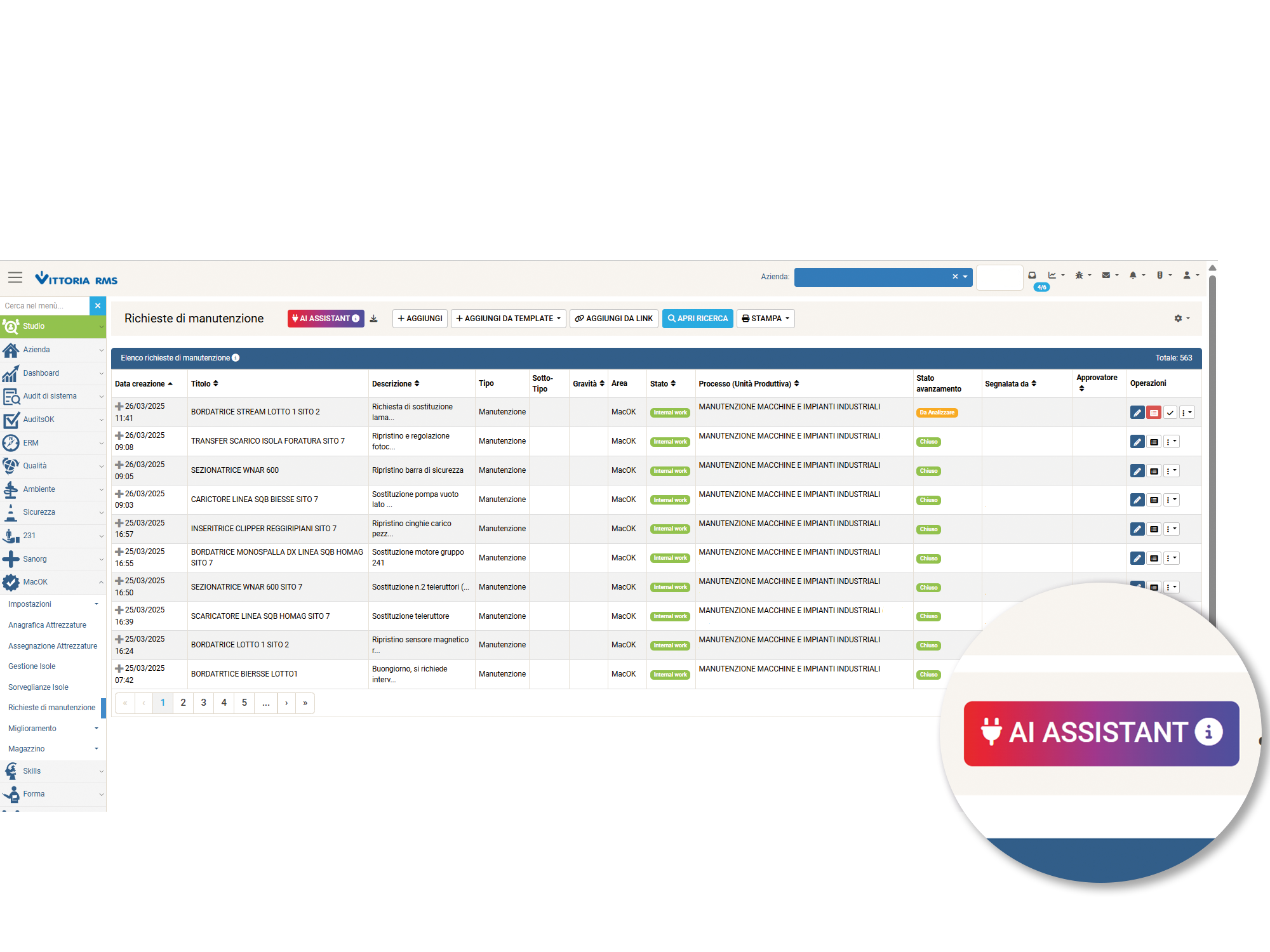

Manage maintenance with artificial intelligence

- Manage Extraordinary Maintenance Requests

- Operators can submit maintenance requests to approvers for the efficient handling of issues or breakdowns.

- Vittoria’s artificial intelligence can read paper-based maintenance reports and automatically enter them into the system.

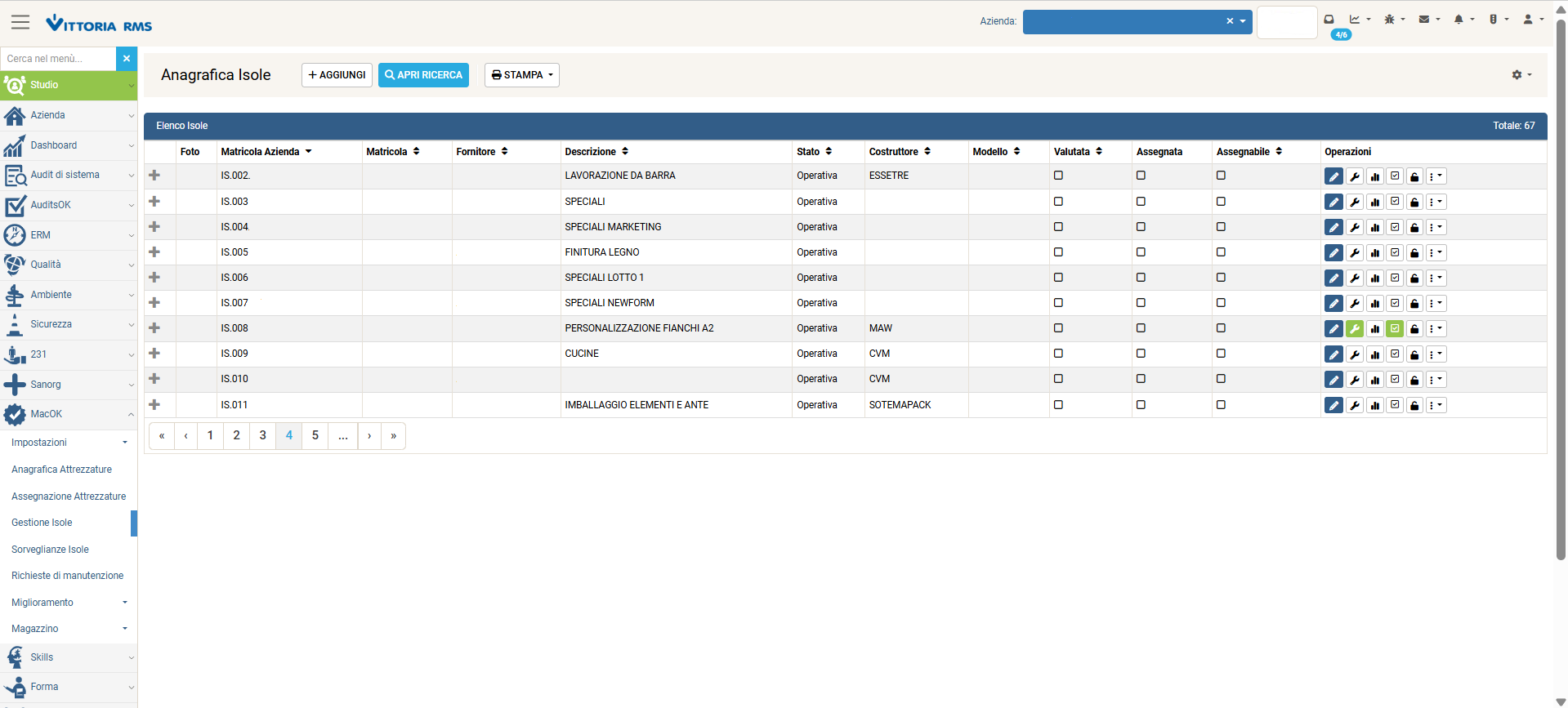

Associate individual machines and create work cells

By associating machines or equipment, you can create work cells and manage their maintenance, documentation, risk assessments, and checklists—everything under control.

The Main Advantages of Vittoria RMS:

To ensure that work equipment and machinery remain safe and efficient, it is essential to manage the maintenance plan while also having easy access to data and documentation related to all activities and compliance requirements concerning Machinery and Equipment.

Define a comprehensive database of all machines with associated control checklists.

Verify compliance with the essential requirements of the Machinery Directive

Plan intervention activities

Machinery Risk Management – The Dedicated Modules

Vittoria RMS Modules

Safety module

Safety Module of Vittoria RMS is designed as a system to facilitate risk assessment, management of legal requirements, planned activities, and all safety and health monitoring for workers. It is integrable with the PPE Management software.

Macok module

Macok is a module designed as a work machinery evaluation system to facilitate the management, archiving, and retrieval of documentation for all activities and compliance requirements related to machinery and equipment.

Safety module

Safety Module of Vittoria RMS is designed as a system to facilitate risk assessment, management of legal requirements, planned activities, and all safety and health monitoring for workers. It is integrable with the PPE Management software.

Macok module

Macok is a module designed as a work machinery evaluation system to facilitate the management, archiving, and retrieval of documentation for all activities and compliance requirements related to machinery and equipment.

Case History

Monia Di Gennaro

RSPP and QHSE Manager - Ponzio Srl

We were looking for software that would bring management back within the company.

Vittoria RMS allowed us to integrate all three systems—Quality, Environment, and Safety—into a single software solution.

Alessandro Lastorina

Personal Safety Leader - P&G

Vittoria RMS is a comprehensive system with the capability to expand and stay increasingly aligned with the evolving needs of Italian companies.

Mauro Evangelisti

Technical manager - Ecoprogramm srl

In Vittoria RMS, there is a strong response to business needs. We use it internally as a firm and also market it in our region as a partner.

Massimo Enrico Magi

Quality & Environment System Coordinator Elica Spa

Vittoria RMS has met our need for precise mappings regarding the risks associated with our machinery and has enabled us to optimally manage our personnel’s safety training.

Franscesco Calciarossa

Quality, Environment, and Safety Manager Rubinitterie Ritmonio Srl

With Vittoria RMS, we have digitized the entire paper-based system, making it more streamlined and immediately accessible to all company functions.

Laura Porfilio

Quality and Safety Manager S.EL.ME.C. Srl

I primarily use Vittoria RMS for the scheduling system, allowing me to keep track of all deadlines, especially for construction sites. The software has relieved me of many of my job’s responsibilities.

Mauro Mencarelli

HSE Manager Di Vincenzo Dino & C. SpA

We needed a tool that would allow us to handle all the records required by regulations, and we immediately found alignment with Vittoria RMS because its approach was highly focused on meeting regulatory requirements.

Carlo Papale

Governance, Risk & Compliance Manager TECHNO Srl

We use Vittoria RMS to consolidate our operational models across all the consultants in our organization and to offer something innovative to our clients, enhancing the effectiveness of our consulting services.

Other solution areas

Discover the solutions offered by corporate management control software.

Audits OK

Audits OK is a module of Vittoria RMS, designed to make conducting audits and inspections simple and fast. Less paperwork, more control over what truly matters in operations.

Regulatory compliance

Vittoria RMS was born from the extensive experience of consultants dedicated to ensuring regulatory compliance for organizations.

Audit control

Vittoria RMS has developed a dedicated module for audit control and the management of actions resulting from the findings identified during their execution.

Environmental management system

The adoption of an Environmental Management System (EMS) in compliance with the UNI EN ISO 14001 standard enables the company to reorganize all its activities more efficiently.

Risk management

Vittoria RMS is the first software capable of mapping any business risk and configuring the right solution in a practical and operational way.

Training and Human Resources Management

With Vittoria RMS, it is possible to analyze data and ensure staff compliance with multiple requirements.

Workplace Safety Management – BBS (Behavior-Based Safety)

BBS improves daily life in the company, empowering each worker and promoting positive behaviors.

Management of skills

Skills is a module of Vittoria RMS designed for the traceability and evaluation of all the competencies of a company resource.

Complaint management

Thanks to Vittoria RMS, complaint management becomes simple and immediate.

Chemical risk management

ChatGPT ha detto:

Vittoria RMS ensures the proper management of chemical risk for the employer.

Energy management

By comparing and analyzing consumption, useful information can be obtained to implement energy efficiency improvement plans.

Product management

Vittoria RMS offers several modules useful for achieving an efficient product management system.

Supplier management

Vittoria RMS allows for monitoring staff access and their compliance, managing contractors clearly, and generating work orders.

Incident management

Vittoria RMS is an essential support tool for properly managing all types of events.

Personnel management

With Vittoria RMS, managing company personnel has never been so simple.

Quality management

Vittoria RMS is a software designed to simplify the management of all activities and compliance requirements related to Quality.

Management systems

Vittoria RMS includes a module for the management, drafting, and distribution of company procedures.

Health and safety in the workplace

The Vittoria RMS solution for workplace health and safety is fully integrated with all company processes.

Environmental sustainability

Measure, monitor, and improve the sustainability, supply chain, and Environmental, Social, and Governance (ESG) performance of your company.